11 TECHNOLOGY FEATURES TO MAKE RESTAURANT INVENTORY MANAGEMENT EASIER

Painless inventory management can supply more profit

Few tasks in hospitality are met with as much dread as managing inventory. It’s a time-intensive, boring, and seemingly endless process. But the value of accurate inventory tracking is high – and inversely, the consequences of doing it poorly can be catastrophic for your bottom line.

Accurate inventory control isn’t just about ensuring you don’t run out of items on shift. Having to eighty-six popular menu items isn’t a desirable customer experience. But an even bigger problem with a lax inventory process is that it’s a recipe for high food costs and profit loss. Proper inventory management includes tracking what comes into the restaurant in supplies, what goes out – including via sale, comp, or waste – and what’s left over. An error in any of those counts can throw your inventory out of whack and make it impossible to understand your profitability.

Accurate counts in every stage of the process help you make smart purchasing decisions that keep your operation right in that happy place – between too much product and too little. And despite the tricks some experienced operators use to make it less painful, inventory is never going to count itself. Luckily, new technologies available today come pretty close. In this article, we’ll discuss three ways smart restaurant inventory management technology can make your inventory process quicker, easier and hyper-accurate.

Maintain Perpetual Inventory

Adding technology to inventory management instantly takes the burden off manual processes like counting. It also makes it easier to identify and maintain the perfect amount of inventory, even when demand fluctuates by day of the week or season. Maintaining this perpetual inventory is made possible with the following technology features:

1. Auto Depletion

Depletion represents how much of an item was used – including via sales, comps or waste. Your POS system is a big help in this area, since it can track which menu items were ordered. If your POS codes are tied to recipes, when menu items are ordered, the items in the recipe will be deducted from your inventory count automatically. There’s still waste and theft to track – but if you can pinpoint the bulk of your depletion, without having to run sales reports and build spreadsheets to track individual item sales, you’ll already be looking at a huge time savings.

2. Waste Tracker

Waste is another form of depletion – and is the hardest to track, since there isn’t any waste information automatically being communicated through the POS system. While tracking waste is still a manual process, it can be much more efficient with technology in play. Instead of keeping handwritten waste logs and compiling the information manually, you can automate the process. Add waste with the click of a button, and you’ll have more accurate, estimated on-hand, and suggested purchase amounts of your products. You can also export and print a report to view waste trends over time.

3. Updated Counts on Delivery

Technology can also streamline counting when it comes to adding inventory through purchasing. With the right system in place, your inventory counts will automatically update when receiving new orders. You can simply adjust between what was ordered and what is delivered, and rely on the software to update everything else, without putting quantities for every new item in the system.

4. Estimated On-Hand Values

After the system accounts for depletion and delivery, the number of products that should be on the shelf is the estimated on-hand value. It’s not a perfectly accurate number, because it won’t reflect untracked waste or theft. But having this solid estimate can guide purchasing decisions and help identify optimal menu specials.

5. Dynamic Par

In terms of inventory, par is the level at which the on-hand quantity of a product is replenished. While pars are decent safeguards against eighty-sixing menu items, they can be improved. Static pars don’t take into account nuanced changes in demand. This can lead to inaccurate ordering, waste, and profit loss. A dynamic par, however, sets par for a number of days rather than product quantities. Paired with a sales forecast, dynamic par ensures you always have enough product for a specific number of days.

For example: If during a busy week, five cases of chicken are enough to last two high-sales days, but during a slow week two cases are plenty for the same amount of days, you can set one powerful, dynamic par to keep you covered for a wide range of business scenarios. With a static par of three or four cases, during a busy week you’d run out of chicken before the next delivery arrives – and during a slow week, you’d be way overstocked.

6. Suggested Purchase Amounts

With technology assisting in depletion and delivery counting, and a dynamic par in place, it’s possible to see suggested purchase amounts. To determine the suggested purchase amount, the system looks at the dynamic par requirement, and calculates the estimated on-hand value and upcoming sales projections, based on historical sales trends. A truly sophisticated system can even turn those suggestions into purchase orders with your vendors in just a few clicks. The time savings these calculations render is significant, regardless of the size of your operation.

Count More In Less Time

Counting takes up the bulk of the time spent managing inventory, but it’s not necessary to count every product in every count, or to count all products in the same way. Counting fewer products more frequently saves time, and gives you a better idea about where you’re spending the most money. Using a variety of counting methods is the best way to make the process as efficient as possible.

Counting takes up the bulk of the time spent managing inventory, but it’s not necessary to count every product in every count, or to count all products in the same way. Counting fewer products more frequently saves time, and gives you a better idea about where you’re spending the most money. Using a variety of counting methods is the best way to make the process as efficient as possible.

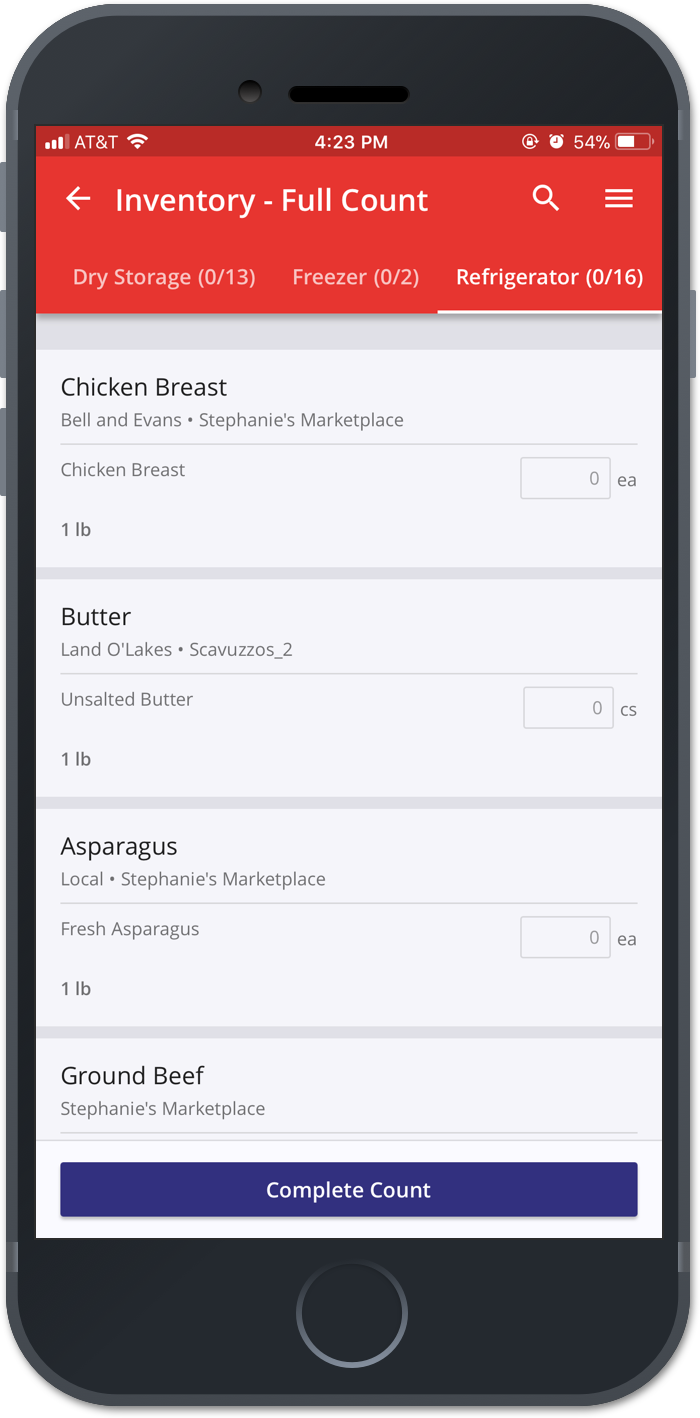

7. Count Types

A full count requires counting every single product. Doing a full count periodically helps ensure overall accuracy, and sheds light on problem areas over time. Full counts are time-consuming, but you can save a significant amount of time by supplementing them with additional counting methods.

Use a class count to count products that are more expensive and/or are ordered more frequently, like meat and poultry. Class counts also provide useful information about how much money you typically allocate to certain product classes – and which products within that class cost the most.

Like class counts, a spot check is useful when you want to double-check quantities before ordering, but it should be done for a smaller number of products than your class count. Likely items for spot counting are highly perishable products like produce and seafood. Since highly perishable items are more susceptible to waste, depletion may not be captured as accurately.

A cycle count helps track items that are unlikely to be included in a class or spot count. If you count 25% of your inventory weekly, rotating products every count, in one month you’ll have counted everything at least once that month, in addition to your other counts.

For example: You might want to perform a full inventory count every month, a cycle count every week, a class count on all meat and poultry products every couple of days, and a spot check on more expensive and highly-perishable products every day that you place an order. This method will save some time and give you the most accurate picture of what’s on hand at any given time.

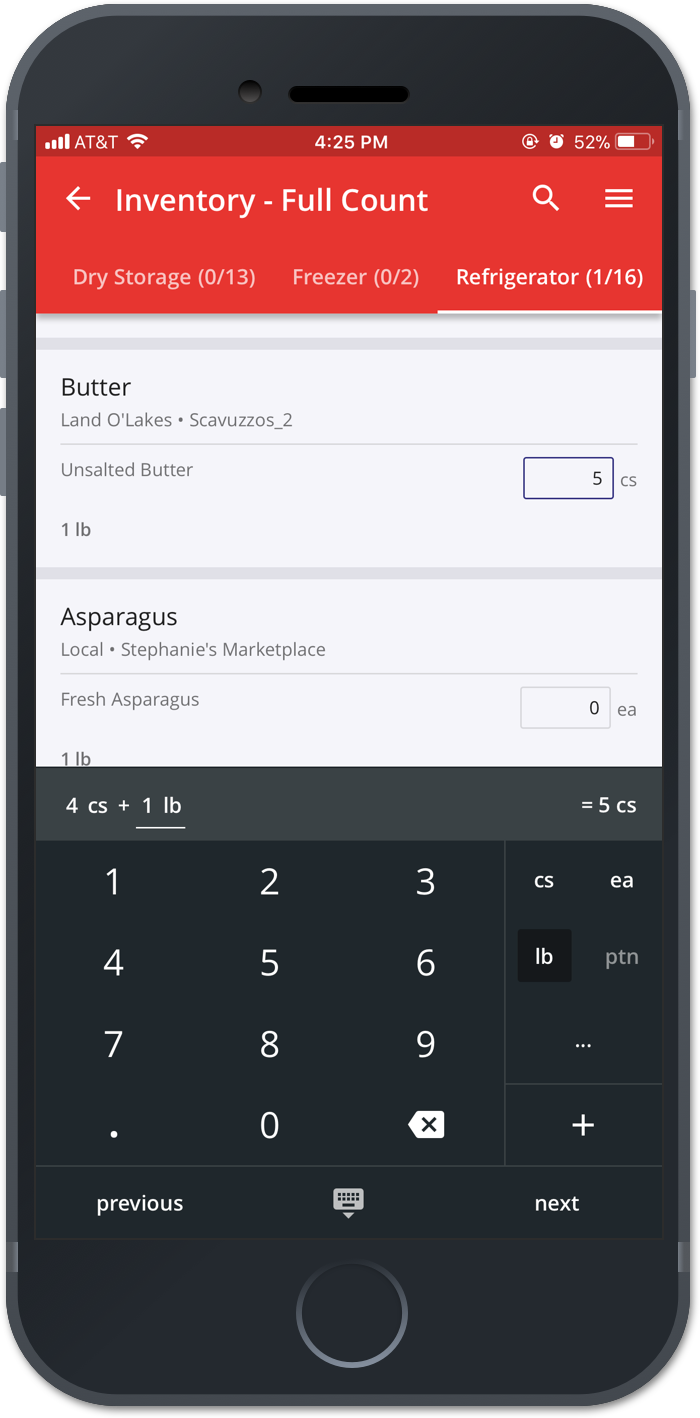

8. Mix and Match Counting Units

Different types of products are counted in different types of units. Most products also need to be able to be counted in two ways: the number of bulk units like cases or crates, as well as individual pieces of broken cases/crates. With the right technology in place, you can easily switch between different types of units during counts, and the system will automatically convert them to your preferred unit of measure. For example, if you’re counting champagne bottles, you can quickly enter two cases + 10 bottles, and the system will automatically render it as 36 bottles.

Different types of products are counted in different types of units. Most products also need to be able to be counted in two ways: the number of bulk units like cases or crates, as well as individual pieces of broken cases/crates. With the right technology in place, you can easily switch between different types of units during counts, and the system will automatically convert them to your preferred unit of measure. For example, if you’re counting champagne bottles, you can quickly enter two cases + 10 bottles, and the system will automatically render it as 36 bottles.

9. Multiple Counters

Divide and conquer inventory tasks for efficiency. A must-have feature in an inventory management solution is the ability to have multiple users logged in and counting at the same time. It should also be able to report when it was completed and what percentage of products were counted.

10. Shelf-to-Sheet Inventory

A major time-saving factor of smart automated inventory systems is the ability to count inventory in the same order as it’s stored on the shelves. Ideally, you should be able to drag and drop items on the list to sort them into the correct order, differentiate between different storage areas, and easily switch between storage areas to make the process as efficient as possible.

11. Offline Functionality

A major failure of some solutions is their dependence on internet or network connectivity. It’s great to manage inventory electronically, but not if you can’t take inventory on a device in the walk-in freezer or the basement stock room without internet connectivity. If you have to count and track products on paper, then enter the numbers into the computer later; you’re spending twice as much time as necessary. Use a system that works offline and offers background autosave, so you can take inventory wherever it’s stored, regardless of connectivity.

Finding the Right Solution

There are a lot of solutions on the market that can help to simplify the inventory process. As with all technologies, some automated inventory solutions are better than others, and some are a better fit for your operation. You need finely-detailed capabilities combined with iron-clad reliability. If your inventory solution introduces more complications than it solves, it’s time to ditch it for a more robust and user-friendly solution. If they don’t include the features mentioned here, you should probably keep looking.

Purchasing and Inventory Management, powered by Avero’s Food Cost Management solution, not only performs all the above, it’s also integrated with US Foods® to make ordering a seamless, automated process. You can also leverage the solution to perfect your product mix, optimize your menu, get cost of goods sold insights and more.

About Avero: Avero powers purchasing and inventory management as part of CHECK® Business Tools, and helps eliminate ordering guesswork, streamlines inventory counts and helps identify sources of waste. Avero also provides Restaurant Operations Intelligence, powered by Avero Sales & Productivity. Learn more about Avero by visiting Reduce Waste: Purchasing and Inventory Management in CHECK Business Tools.

Visit the CHECK Resource Center for more articles full of valuable insights, industry analysis and helpful tools that can help you grow your business.